What is Inox Steel? A Complete Guide to Grades, Uses, and Properties

What is Inox Steel and What Does “Inox” Mean?

If you’ve ever shopped for high-end kitchen appliances, browsed for marine hardware, or admired modern

architectural fixtures, you’ve almost certainly encountered the term “Inox.” You may

have seen it stamped on a premium watch, a kitchen sink, or a structural railing. But what exactly

is material Inox? Is it a specific brand, a special type of coating, or something else entirely?

The simplest answer is also the most direct: “Inox” is just another name for stainless

steel.

The term “Inox” is a shortened form of the French word inoxydable. When broken down, the

etymology is simple: “in-“ means “non” and “oxydable” means “oxidizable” (or “rusting”).

Therefore, the inoxydable meaning is literally “non-oxidizing” or “a material

that does not rust easily.” This elegant term was adopted globally as a common name for

stainless steel, especially in European and technical contexts.

So, when you see a product labeled as “inox steel” or “inox stainless steel,” you are simply looking at a

product made from standard stainless steel. The name itself emphasizes the material’s most

important and valued property: its remarkable ability to resist corrosion and rust.

What Makes Inox Material Special? The Magic of Chromium

The secret to inoxidable steel’s resilience lies in its chemical composition. All steel is

fundamentally an alloy (a mixture of metals) of iron and carbon. What transforms regular steel

into stainless steel (Inox) is the addition of a significant amount of the element

chromium.

By definition, any Inox material must contain a minimum of 10.5% chromium by mass.

This chromium is the “magic ingredient” that gives the steel its “stainless” properties. But how

does it work?

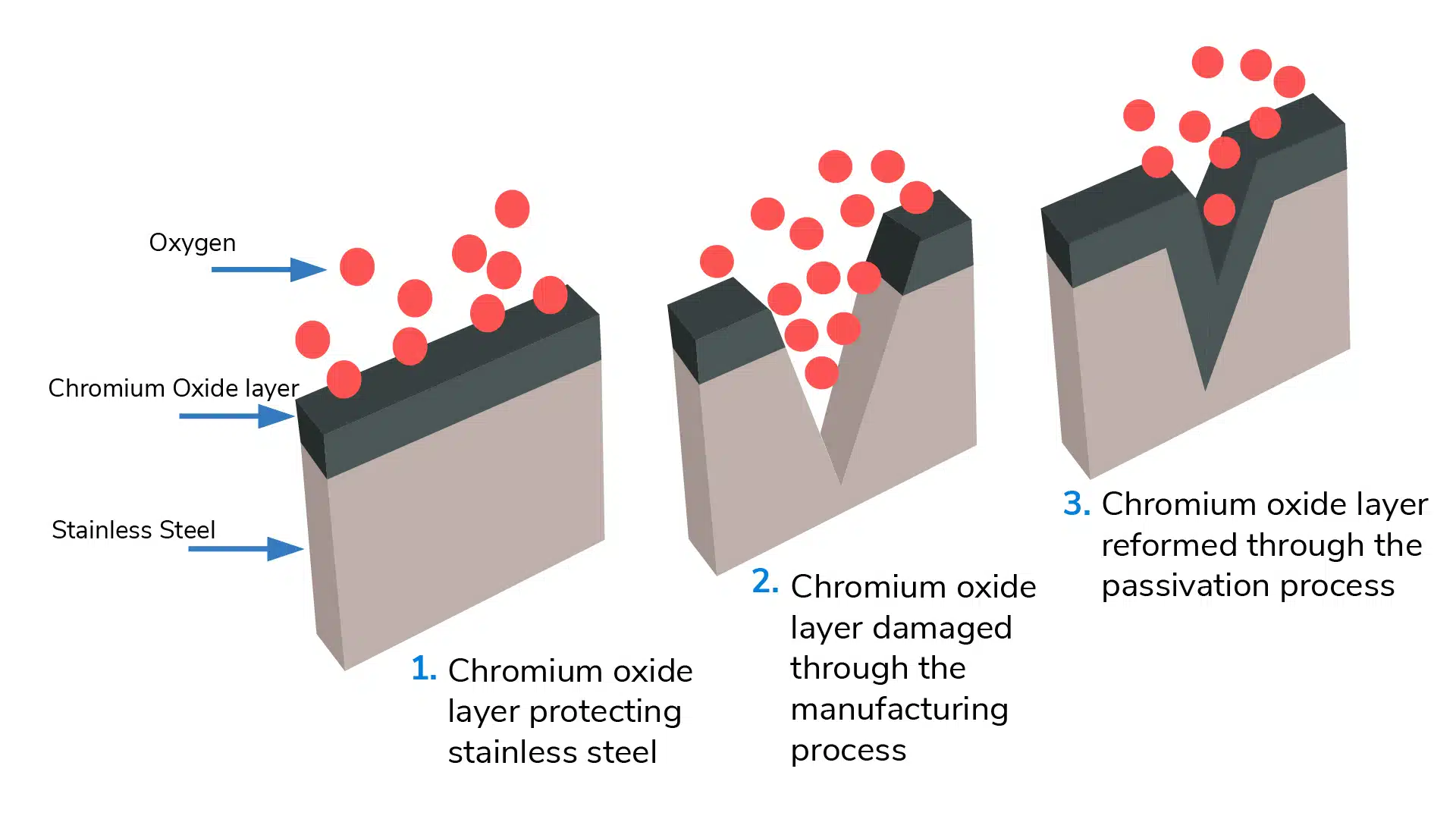

Understanding the “Passive Layer”: Steel That Heals Itself

The protection offered by chromium is not a coating; it’s an active, integral part of the steel itself.

When the chromium in the alloy is exposed to oxygen (even just the oxygen in the air), it undergoes a

chemical reaction. It forms a very thin, stable, and invisible layer on the metal’s surface

called a “passive layer” or “chromium oxide layer.”

This passive layer acts as a durable, non-porous shield, instantly sealing the vulnerable iron in the

steel from the environment (like water and air). This is what prevents rust and corrosion from

forming.

[A diagram here showing how the chromium oxide passive layer forms would be very helpful to

visualize this concept.]

What makes this material Inox truly incredible is that this shield is self-healing.

If the surface is scratched, cut, or damaged, the newly exposed chromium in the steel

immediately reacts with oxygen and reforms the protective passive layer, sealing the damage before rust

can ever begin. This is a key difference from coated materials like painted or galvanized

steel, where a scratch exposes the base metal to permanent corrosion.

Is All Inox Steel the Same? Exploring the Grades

No. “Inox steel” is a broad term that covers several different families and hundreds of specific grades.

While all are defined by their chromium content, different alloying elements—like

nickel, molybdenum, and manganese – are added to fine-tune properties for strength,

hardness, magnetism, and specific types of corrosion resistance.

The grades are primarily grouped into four main families:

1. Austenitic (The Workhorses: 300 & 200 Series)

This is the most common and widely recognized family of Inox stainless steel. They are known for

their excellent formability (easy to bend and shape), superior corrosion resistance, and are

non-magnetic.

Inox Grade 304 (18/8)

This is the most popular grade of Inox steel worldwide. It typically contains 18% chromium and 8%

nickel, which is why it’s often called 18/8 stainless steel. Grade 304 offers

excellent corrosion resistance in most environments, making it the standard for kitchen appliances, food

processing equipment, sinks, cutlery, and general architectural trim.

Inox Grade 316 (Marine Grade)

This is the superior choice for harsh environments, especially coastal areas with salt in the air.

Grade 316 contains the same 18% chromium as 304, but it adds about 2-3% of another element:

molybdenum. This molybdenum significantly enhances its resistance to

chlorides – specifically, salt. This addition makes 316 the essential choice

for boat fittings, coastal railings, and any application constantly exposed to salt spray.

2. Ferritic (The Magnetic Group: 400 Series)

This family of Inox (including Grade 430) has a different crystal structure, which

means it is magnetic. While it doesn’t have the same high-level corrosion

resistance as the 300 series, it’s still highly resistant to oxidation and is very cost-effective (it

lacks the expensive nickel). It’s common in applications like automotive exhaust systems,

indoor decorative trim, and some refrigerator doors (where magnets need to stick).

3. Martensitic (The Hard & Strong Group: 400 Series)

Also part of the 400 series (like Grades 410 and 420), martensitic grades are known for

their exceptional strength and hardness, which is achieved through heat treatment.

This hardness, however, comes at the expense of some corrosion resistance compared to

austenitic grades. You’ll find martensitic Inox steel used for high-wear items like

professional knives, surgical instruments, and industrial valves.

4. Duplex (The High-Performance Hybrid)

As the name suggests, Duplex stainless steels (like Grade 2205) have a mixed microstructure

of both austenite and ferrite. This hybrid structure gives them a “best of both worlds”

profile: they have a much higher strength (often twice as strong as 300 series grades) and superior

resistance to chloride stress corrosion cracking. For critical infrastructure in harsh

environments, like chemical plants or bridges exposed to saltwater, Duplex grades are an increasingly

popular, high-performance solution.

Inox Families at a Glance: Comparison Table

Here is a simple table to help you compare the main families of Inox stainless steel:

| Inox Family | Common Grades | Key Properties | Common Applications |

|---|---|---|---|

| Austenitic | 304, 316 | Non-magnetic, excellent corrosion resistance, highly formable. | Boat railings (316), outdoor kitchens (304), architectural trim. |

| Ferritic | 430 | Magnetic, good corrosion resistance, cost-effective. | Indoor appliances, automotive exhaust, interior decorative trim. |

| Martensitic | 410, 420 | Magnetic, very hard and strong, moderate corrosion resistance. | High-end knives, surgical instruments, industrial valves. |

| Duplex | 2205 | Magnetic, 2x stronger than 300 series, extreme corrosion resistance. | Critical marine hardware, chemical plants, bridges in saltwater zones. |

Table data adapted from source.

Inox vs. Other Metals: A Quick Comparison

How does Inox steel stack up against other common metals?

- Inox vs. Aluminum: Aluminum is fantastic for being lightweight and is also highly

corrosion-resistant. However, Inox is significantly stronger, harder, and more

resistant to scratches and dents. This makes Inox more durable for high-traffic

applications like countertops, railings, or industrial equipment. - Inox vs. Carbon Steel: Regular carbon steel (or “mild steel”) is very strong and

less expensive, but it has one major, defining flaw: it rusts easily.

Carbon steel *requires* a protective coating like paint or galvanizing. Inox is chosen when the

strength of steel is needed, but the project demands long-term, built-in corrosion resistance that

carbon steel cannot provide on its own.

Where is Inox Steel Used? Key Applications

Because of its clean, modern look and its incredible resilience, Inox material is a top choice for

projects, especially in regions where humidity, sun, and salt are constant challenges.

- Marine and Coastal: This is where Inox truly shines. Grade 316 Inox

is the non-negotiable standard for boat railings, cleats, anchors, and any hardware constantly

exposed to saltwater. Its ability to resist pitting and corrosion is essential for safety

and longevity on the water. - Architecture and Construction: Look at the balconies, railings, and window frames of

modern buildings. That clean, bright, and rust-free finish is almost always Inox steel.

It provides structural strength while withstanding salt in the air, requiring far less

maintenance than painted carbon steel. - Outdoor Kitchens and Entertainment: Inox is the preferred material for high-end

outdoor kitchens, grills, cabinets, and countertops. It can handle intense sun without

fading, withstand rain without rusting, and is hygienic and easy to clean after a

barbecue. - Food & Beverage Industry (and Medical): From commercial kitchens to breweries, Inox

steel is used for sinks, prep tables, and tanks. Its non-porous surface

doesn’t harbor bacteria, is easy to sanitize, and won’t react with acidic foods, ensuring purity and

safety. This is the same reason it’s essential for medical and surgical instruments.

Conclusion: Why Inox is a Smart Investment

So, what is Inox steel? It is the proven, reliable, and beautiful material we all know as stainless steel.

The meaning of Inox is a direct promise of its performance: it is a material engineered to

resist oxidation and rust, providing a lifetime of service and style.

Whether you are fabricating a high-end architectural feature, outfitting a yacht, or building the ultimate

outdoor kitchen, choosing a high-quality material Inox – and the *correct grade* like 304 or 316 – is a

smart investment in your project’s longevity and future.

Contact

Contact C & R Metals today for expert advice and premium metal supply in South Florida. Call (305) 634-2111 or email sales@crmetals.net

to speak with our team about your project needs. Visit us at 2991 NW North River Dr., Miami, FL, 33142.

We’re open Monday to Friday from 7:30 AM to 4:30 PM, and Saturday from 8:00 AM to 1:00 PM. Closed on Sunday.

Proudly serving Miami-Dade County, Broward County, Monroe County, and Palm Beach County.