Welding

M-F 7:30AM - 4:30PM / Sat 8:00AM - 1:00PM / Sun - Closed

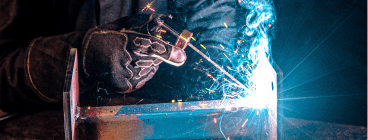

Expert Welding Services at C & R Metals

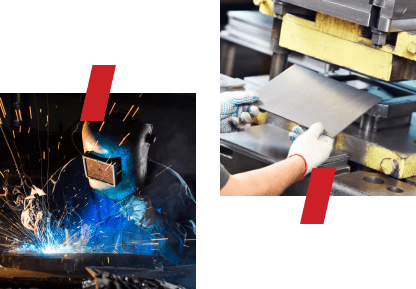

At C & R Metals, we provide the best welding services to meet all your metalworking needs. Our experienced welders and state-of-the-art equipment ensure precision and quality in every project. Whether you need a simple repair or a complex fabrication, we have the expertise to handle it all. No job is too small or too large; we provide fast service for every customer and project. We take pride in our meticulous attention to detail and commitment to excellence. Trust us to deliver durable and reliable welds that stand the test of time.

Why Choose Our Welding Services?

Mobile Versatility

Our welding services can handle a wide range of metals and project sizes. We offer mobile services if you need welding for an on-site project.

Precision

Our skilled welders use advanced techniques and equipment to ensure precise, clean welds, meeting the highest standards of quality.

Durability

We focus on creating strong, durable welds that stand the test of time, ensuring the longevity and reliability of your projects.

Customer Satisfaction

We are committed to providing exceptional service and ensuring our customers are fully satisfied with the results.

Our Welding Capabilities

We specialize in welding a variety of metals of any size and shape, big or small.

Some of our most requested metals customers need welded include:

Our Welding Techniques

TIG (Tungsten Inert Gas) Welding

Also known as Gas Tungsten Arc Welding (GTAW), TIG welding uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation and other atmospheric contamination by an inert shielding gas, usually argon or helium. This process is known for its precision and is often used for welding thin sections of stainless steel and non-ferrous metals like aluminum, magnesium, and copper alloys. TIG welding provides high-quality, clean welds but requires a high level of skill and is generally slower than other welding methods.

MIG (Metal Inert Gas) Welding

MIG welding, or Gas Metal Arc Welding (GMAW), uses a continuous solid wire electrode that is fed through a welding gun into the weld pool. The weld area is protected from atmospheric contamination by a shielding gas, which can be argon, helium, or a mix of gases. This method is popular for its speed and ease of use, making it suitable for both thin and thick materials. MIG welding is commonly used in automotive repair, manufacturing, and construction. It’s a versatile process that can be semi-automatic or fully automatic.

Stick Welding

Stick welding, or Shielded Metal Arc Welding (SMAW), uses a consumable electrode coated in flux to create the weld. An electric current forms an arc between the electrode and the metals, melting both to form the weld pool. The flux coating disintegrates, providing shielding gas and slag to protect the weld from contamination. Highly versatile and less sensitive to wind and drafts, stick welding is ideal for mobile welding needs, including construction, repair work, and heavy steel structures.

Check out our completed projects and those in process to see how we go above and beyond with our welding services.

Additional Metalworking Services

In addition to our premier waterjet services, C & R Metals, Inc. offers a comprehensive range of metalworking services to meet all your project needs.

Call or Stop By Today

Ready to start your next project or just need quality metal parts stocked locally that can be cut to order or delivered in the exact quantity you need? Contact C & R Metals today to discuss your metalworking needs and discover how our expertise can bring your vision to life. Our team of professionals is here to provide you with the highest quality products and services, ensuring your complete satisfaction.